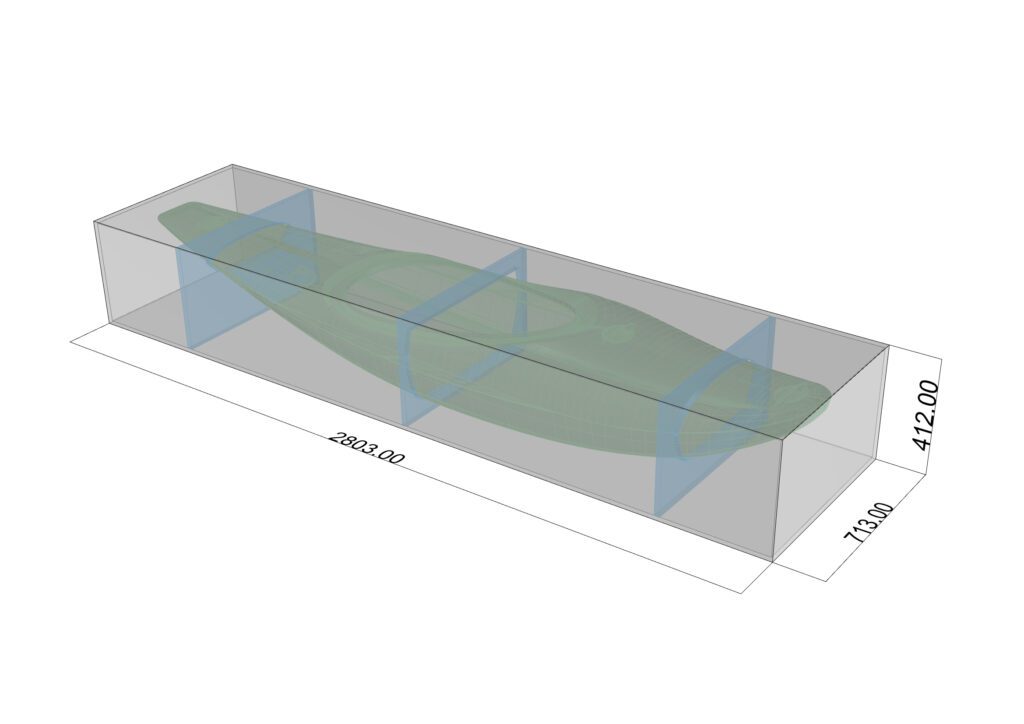

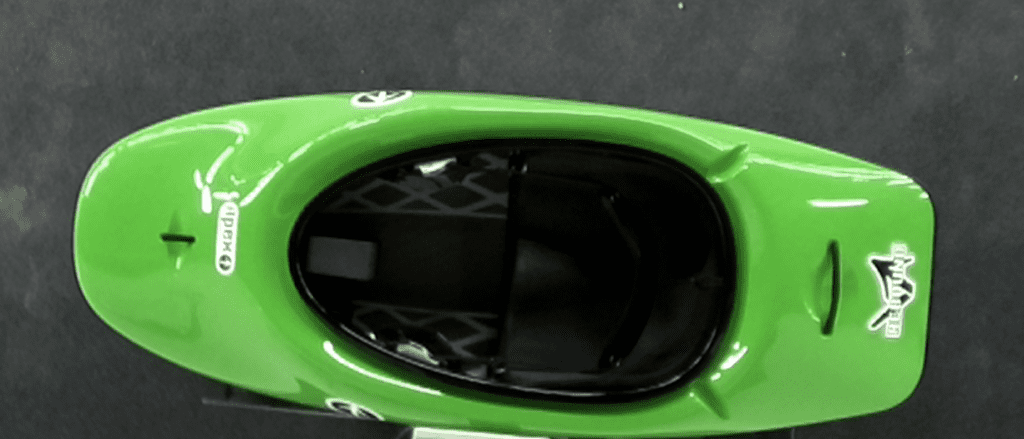

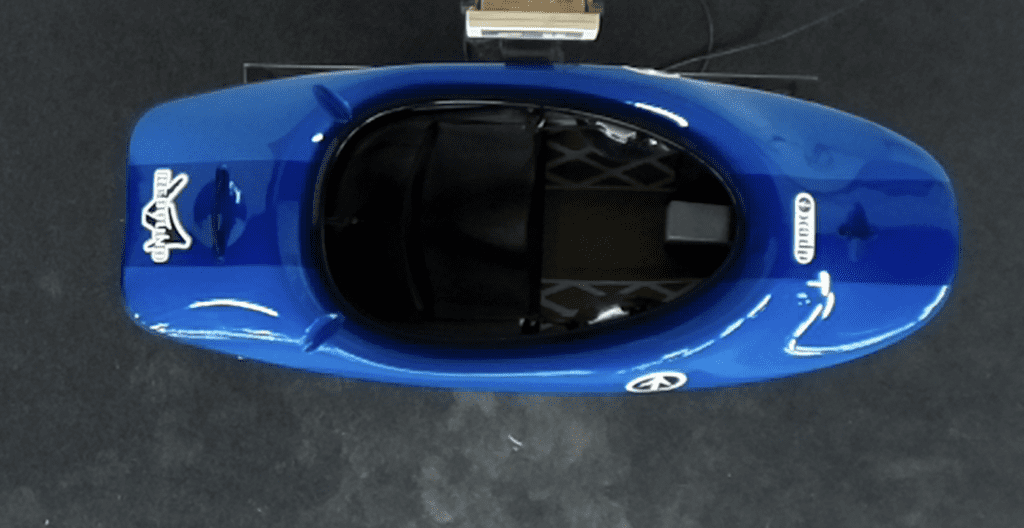

What a ride it has been getting to the place! I am very proud of these boats. The design is ready for prime time and it is my first boat that I designed with my new design partner, Mark Nordstrom. Mark’s job of designing with me wasn’t easy. It may have felt like drinking through a fire hose to him on this design. So much to learn about each other to communicate all of the nuances properly. I am honored that he is on Team Apex with me. A true CAD product design genius. Now he is learning about whitewater kayaks and we have two separate designs under our belts together. The Rebound and the Ringer.

Nelo- Unbelievable skills, caring, and knowledge, combined with an owner operator (Nelo- National Champion Sprint Kayak Racer), and kayaker plant manager, Andre’.

Andre’ will race you in a kayak before work and then work with his 200 employees managing all of the little details of a very complex factory setting. His brain goes 100mph all day, as he texts with one factory member, while talking to another, and glancing up to see how a boat is looking from his “tower of power” desk in the middle of the mayhem. Everywhere around the factory are equally qualified employees and managers doing their respective jobs. Gomes is managing all things in the sewing facility, such as making our boat bags and back bands. Sergio is ruling the laminating facility with the precision of a doctor overseeing an operating table. This stage of making the boats is so critical to get done right that mistakes are not acceptable. He does it with a smile and the confidence, speed, and precision that you want to just watch him work. He has a couple of dozen workers molding many types of boats, cockpit rims, etc. etc. all at the same time. He is directly on the Apex project and his hands have touched each Rebound, Ringer, and Tyr made. Henrique, used to be plant manager, and did a great job, but wanted a simpler life and requested to be on boat assembly. I knew there was something special about him when he was working on the Rebound prototype with me. I mentioned to him, “Man, you could be a great manager the way you work with those around you and know absolutely everything about this stage of the process.” He just smiled and said, “no thanks, I like being hands on in my job.” I am not mentioning everyone, as I am out of writing time, sorry. The CNC shop, etc. etc. are all impressive at what they do.

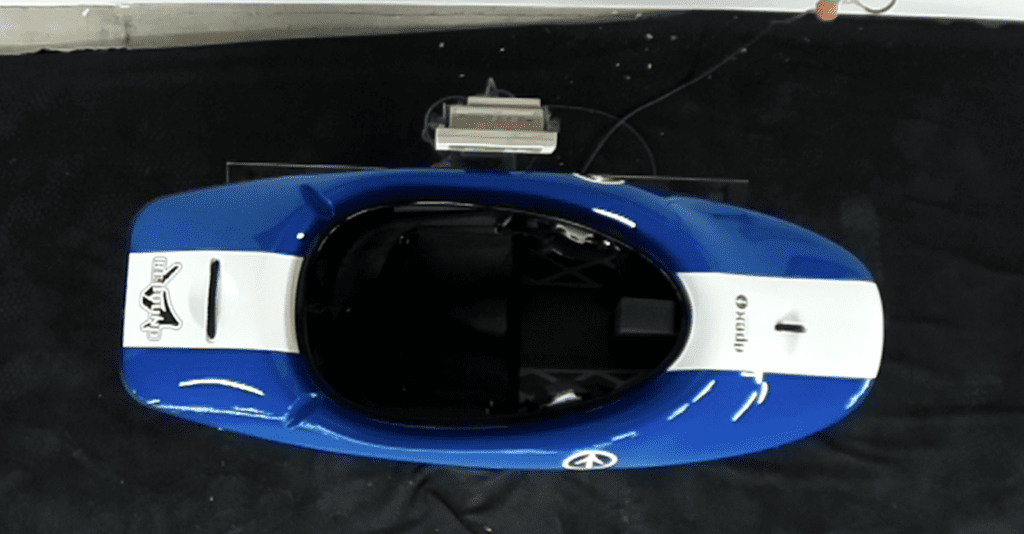

What does this all have to do with the pictures you are seeing here? It means that the end product had the right people working on it at every stage of the process. The design, down to every step of the manufacturing process is using best practices, the best materials, and the best people.

In 5 days these boats will be in cardboard boxes, and loaded onto a 40’ shipping container heading to Rock Island. From there, my new customer service/shipping manager Will Price will be helping me match up boats with kayakers. Nelo is working every day to make enough boats to fill the container. It has 43 on the schedule today, but I am hoping to get 48 on it. That is how many we think will fit with 15 of them being the Tyr fishing kayak (big boats).

I am offering every one of these boats to dealers first and if there are any not spoken for once the container is loaded and we know exactly what is on it, we’ll open the rest of the boats to be purchased directly from Apex.

I hope at least one of these boats are a color that look good to you! There will be a few more colors coming. If you are not a Medium size for the Rebound, don’t stress. The Small, Large, and XL, and XS are coming your way! It takes time and one at a time.

See you on the river!

🙂

EJ